Reasons and solutions for the deviation of PTFE conveyor belt

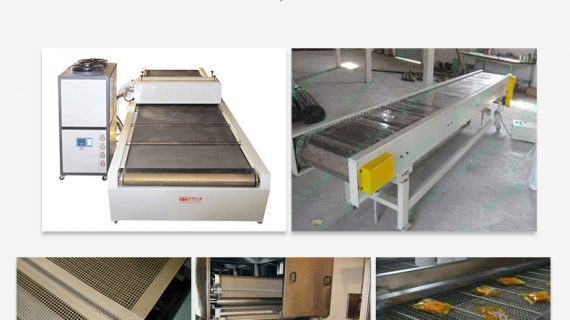

PTFE conveyor belt deflection is one of the most common failures when using PTFE conveyor belt on conveyors. There are many reasons for deviation. The main reason is the low installation accuracy and poor daily maintenance. The following are some common reasons and solutions for the maintenance of conveyors using PTFE conveyor belt.

Conveyor with PTFE conveyor belt During the installation process, the head and tail rollers and the intermediate rollers are on the same center line as far as possible, and parallel to each other to ensure that the conveyor belt is not biased or less biased. In addition, the strap joints should be correct and the circumferences on both sides should be the same.

The phenomenon, causes and solutions of PTFE conveyor belt slipping:

-Conveyor failure phenomenon: PTFE conveyor belt slips.

-Conveyor failure reason: When the PTFE conveyor belt is in normal operation, the belt speed should not be lower than 95% of the roller speed. If the friction between the roller and the PTFE Mesh conveyor belt is insufficient, the PTFE conveyor belt is prone to slippage. There are many reasons for the insufficient friction between the roller and the PTFE conveyor belt. Common ones are: load start, insufficient friction coefficient on the surface of the roller, and insufficient tension. The reasons for the insufficient friction coefficient on the surface of the roller are: the surface of the roller is too much worn, the belt is too wet or sticky, the surface of the belt is stuck with material (easy to be melted by water); the reasons for insufficient tension are: The tight stroke is not enough, the weight of the counterweight is not enough, and the PTFE conveyor belt is too long.

Trouble solution for conveyor: clean the surface of the roller, dry the PTFE conveyor belt, clean the PTFE conveyor belt, adjust the tension stroke, increase the weight of the counterweight, and shorten the length of the PTFE conveyor belt.

The phenomenon, causes and solutions of conveyor deviation:

-Conveyor failure phenomenon: PTFE conveyor belt deviation.

-Conveyor deviation detection site and treatment methods:

Check the misalignment of the transverse centerline of the idler and the longitudinal centerline of the conveyor. If the non-coincidence value exceeds 3 mm, it should be adjusted with the long mounting holes on both sides of the roller set. The specific method is which side of the PTFE conveyor belt is biased, which side of the roller set moves forward in the direction of advancement of the PTFE conveyor belt, or the other side moves backward.

The main PTFE coatings products for China Wellflon Group such as: PTFE Glass Cloth,PTFE Glass Cloth Tape,PTFE Skived Film Adhesive Tape,PTFE Open Mesh,PTFE Conveyor Belt,PTFE Baking Sheet,PTFE Architecture Membrane. Welcome to contact us if you have regular related requirement!